Facing the future, Stick together, With faithfulness and sharing

At present, the domestic light-curing paint inks are mainly free

radical systems.Light curing ink coatings only account for 1-3% of the global

ink coatings. Free radical light curing ink coatings do not achieve the

expected effect in some applications. There are still some bottlenecks that

need to be broken through. Some defects need to be improved, such as too large

shrinkage, poor weather resistance and high halogen content.The cationic system

can compensate for these defects of the free radical system.

Materials and cationic curing resins (transparent coatings,

inks, adhesives, stereolithography)Light curing technology is a kind of light

processing technology that enables liquid resin to be polymerized into solid

state by ultraviolet light irradiation of a certain wavelength. It saves

energy, does not contain solvents, has a protective effect on the ecological

environment, and does not emit toxic gas and carbon dioxide to the atmosphere.

Therefore, it is known as a "green technology".

A certain proportion of alicyclic epoxy resin needs to be added

to the light curing coatings and inks.

The curing speed is fast, the shrinkage rate is low, the surface

is wrinkle-free, the adhesion force is strong, and the corrosion resistance is

strong. It not only retains the properties of the original epoxy resin, but

also greatly accelerates its curing speed, so that it cures within minutes or

even seconds, greatly improving the labor productivity.

The hardened paint film and ink are obtained by light curing

technology, which has the following advantages: energy saving, environmental

protection, high quality and high efficiency.

Adhesive

Electronic encapsulation

Electronic materials (plastic-encapsulated semiconductor,

LED, bottom filler)

The

alicyclic epoxy resin related products of TTA are the main resins in low

halogen or even halogen-free electronic encapsulation adhesive, and can

effectively improve the thermal resistance of the colloid.

In recent years, the LED industry has developed rapidly, and

industry experts are generally optimistic about the market prospects. TTA21 was

used by Guangzhou Huili as a representative of many packaging glue

manufacturers to produce direct-plug LED packaging glue more than years ago,

effectively ensuring the service life of outdoor LED display and other terminal

products. With the continuous breakthrough of LED lighting technology, TTA

products have a new stage that can play its own advantages.TTA21, TTA3150 and

other products are used in patch LED encapsulation adhesive by companies such

as Shanghai Lianlang and Shenzhen Guanggu. The high-temperature resistance of

high-power encapsulation adhesive is close to that of expensive imported silica

gel, and the 0.5W grade encapsulation adhesive can achieve zero optical decay

in 2000 hours.

Electronic materials (plastic-encapsulated semiconductor, LED, bottom filler)

The

alicyclic epoxy resin related products of TTA are the main resins in low

halogen or even halogen-free electronic encapsulation adhesive, and can

effectively improve the thermal resistance of the colloid.

In recent years, the LED industry has developed rapidly, and

industry experts are generally optimistic about the market prospects. TTA21 was

used by Guangzhou Huili as a representative of many packaging glue

manufacturers to produce direct-plug LED packaging glue more than years ago,

effectively ensuring the service life of outdoor LED display and other terminal

products. With the continuous breakthrough of LED lighting technology, TTA

products have a new stage that can play its own advantages.TTA21, TTA3150 and

other products are used in patch LED encapsulation adhesive by companies such

as Shanghai Lianlang and Shenzhen Guanggu. The high-temperature resistance of

high-power encapsulation adhesive is close to that of expensive imported silica

gel, and the 0.5W grade encapsulation adhesive can achieve zero optical decay

in 2000 hours.

The alicyclic epoxy resin is used in 3D printing, which has the

characteristics of low curing shrinkage, low VOC, low viscosity, nearly

colorless and transparent overall, good yellowing resistance and weather

resistance.

電子材料(塑封半導體、LED、底部填充膠)

TTA的脂環(huán)族環(huán)氧樹(shù)脂相關(guān)產(chǎn)品,在低鹵甚至無(wú)鹵的電子封裝膠中做為主體樹(shù)脂,并且能有效提高膠體的耐熱性能。

近年來(lái)LED行業(yè)發(fā)展迅猛,業(yè)內專(zhuān)家也普遍看好市場(chǎng)前景,TTA21多年以前就被以廣州惠利為代表眾多封裝膠廠(chǎng)家用于生產(chǎn)直插式LED封裝膠,有效的保證了戶(hù)外LED顯示屏等終端產(chǎn)品的使用壽命;隨著(zhù)LED照明技術(shù)的不斷突破,TTA的產(chǎn)品又有了一個(gè)能發(fā)揮自身優(yōu)點(diǎn)的新舞臺,TTA21和TTA3150等產(chǎn)品被上海聯(lián)浪和深圳光谷等企業(yè)用于貼片式LED封裝膠中,在中大功率封裝膠中耐高溫性能接近價(jià)格昂貴的進(jìn)口硅膠,在0.5W級別的封裝膠中能做到2000小時(shí)零光衰。

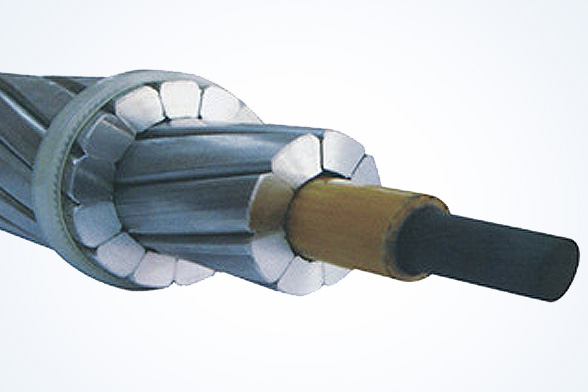

Electrical insulating materials (electrical

insulating varnish, resin insulator, gas insulated combined electrical

equipment)

As the heart of motor, the performance of insulation system

directly affects the reliability and operation life of motor.Thermal breakdown

of insulation caused by dielectric loss is a common concern of motor

insulation, especially in the insulation of variable frequency motor, the

degree of insulation heating is much greater than that of power frequency

motor.Therefore, higher requirements are put forward for the insulation

impregnated resin, which needs higher heat resistance and lower dielectric loss

to ensure the safe operation of the motor insulation system.

As the raw material of impregnating resin,

TTA21 series products have high performance, excellent electrical performance

and low dielectric loss, and are suitable for insulation treatment of

high-power traction motor coils and windings.VPI resin related data

The

alicyclic epoxy resin has good heat resistance, mechanical properties and

weather resistance, especially its small viscosity and long application period.

It is especially suitable for wet lamination and winding forming to produce

high-strength heat-resistant composite materials, and has been applied in

deep-water submarines and missiles.