Facing the future, Stick together, With faithfulness and sharing

Electrical casting materials refer to a kind of epoxy insulating materials used for casting insulating parts, transformers or dry transformers. Its formula adopts thermal curing system of epoxy resin anhydride, in which the bisphenol A epoxy resin is used most, and it enjoys many advantages such as excellent manufacturability, high strength of cured product, corrosion resistance and electrical properties. However, problems such as high viscosity, limited powder addition ratio, insufficient heat resistance and weather resistance always occur due to technological restrictions and use environment of terminal products. The epoxy bond of the cycloaliphatic epoxy resins is directly connected to alicyclic structure, which could improve the crosslinking density of the cured substance significantly, thereby improving heat and weather resistance and electrical insulation. In addition, the viscosity of the cycloaliphatic epoxy resins is extremely low, which contributes to the significant dilution effect. Therefore, cycloaliphatic epoxy resins can make up for the deficiency of bisphenol A epoxy resins applied in the electrical casting materials system. The combination of both materials can improve manufacturability, as well as making terminal electrical insulation products safer.

1. Basic information and specifications & parameters of cycloaliphatic epoxy resins TTA21

1.1 Basic information

|

Chinese name

|

3,4-環氧環己基甲酸-3',4'-環氧環己基甲酯

|

|

English name

|

3,4-Epoxycyclohexylmethyl- 3',4'-Epoxycyclohexane Carboxylate |

|

CAS No.

|

2386-87-0 |

|

Structural formula

|

|

|

Molecular weight

|

252.31 |

|

Molecular formula

|

C14H20O4 |

1.2 Specifications and parameters

|

Designation

|

TTA21S |

TTA21L |

TTA21P |

|

Appearance

|

Colorless and transparent liquid

|

||

|

Content

|

90% min |

95% min |

97% min |

|

Epoxide equivalent

|

128-145 g/mol |

126-135 g/mol |

126-135 g/mol |

|

Chromaticity

|

100 APHA max |

50 APHA max |

50 APHA max |

|

Viscosity

|

180-450 cP |

220-300 cP |

220-300 cP |

|

Moisture content

|

0.05% max |

0.05% max |

0.05% max |

|

Acid value

|

0.1% max |

\ |

\ |

|

Total chlorine

|

\ |

\ |

100 ppm max |

|

Specific Gravity

|

1.150-1.180 |

||

2. Basic performance data of TTA21P before and after thermal curing with methylhexahydrophthalic anhydride

|

Cycloaliphatic epoxy resin

|

TTA21P |

Parts |

100 |

|

Anhydride curing agent

|

MHHPA |

Parts |

130 |

|

Accelerant

|

AO-4 |

Parts |

2 |

|

Viscosity

|

25℃ |

mPa·s |

160 |

|

Thermal properties

|

Tg-DSC |

℃ |

226 |

|

△H |

J/g |

350 |

|

|

Peak temperature

|

℃ |

195 |

|

|

Tg-TMA |

℃ |

225 |

|

|

α1 |

μm/(m·℃) |

56 |

|

|

α2 |

μm/(m·℃) |

174 |

|

|

Tg-DMA E' |

℃ |

189 |

|

|

E“ |

℃ |

208 |

|

|

tane |

℃ |

231 |

|

|

Mechanical properties

|

Impact strength

|

KJ/m2 |

5.95 |

|

Bending strength

|

MPa |

125 |

|

|

Flexural modulus

|

MPa |

3120 |

|

|

Tensile strength

|

MPa |

57 |

|

|

Tensile modulus

|

MPa |

3205 |

|

|

Elongation at break

|

% |

2.8 |

|

|

KIC |

Mpa*m? |

0.45 |

|

|

Electrical property

|

Volume resistivity

|

Ω*cm |

1.168×1016 |

|

Surface resistivity

|

Ω |

1.191×1015 |

|

|

Dielectric constant

|

C2/(N*M2) |

3.0752 |

|

|

Dielectric loss

|

\ |

0.0042 |

|

|

Hardness

|

Shore D |

\ |

89 |

|

Water absorption

|

25℃/24hr |

% |

1.05 |

|

Curing conditions

|

100℃×2hr + 140℃×2hr + 180℃×1hr |

||

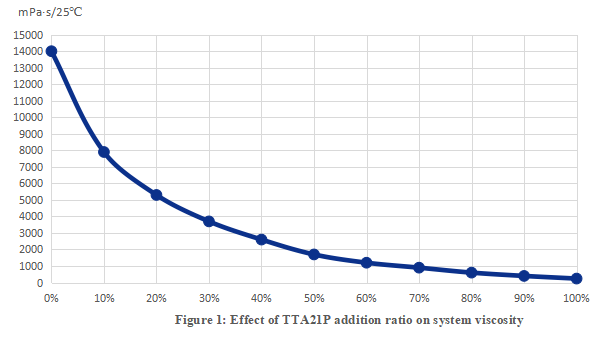

3. Effect of TTA21P addition ratio on system viscosity

3.1 Test materials: TTA21P/128

3.2 Conclusion: As shown in Figure 1, with the increase of TTA21P addition ratio, the system viscosity decreases rapidly, which reflects the obvious dilution effect of TTA21P.

4. Effect of TTA21P addition ratio on Tg of cured products

4.1 Test materials and curing conditions: TTA21P/128/ MHHPA/ BDMA and 100℃×2h+140℃×2h+180℃×1h.

4.2 Conclusion: As shown in Figure 2, with the increase of TTA21P addition ratio, Tg value of the cured product increases significantly, which reflects that TTA21P can improve the heat resistance of the material significantly.

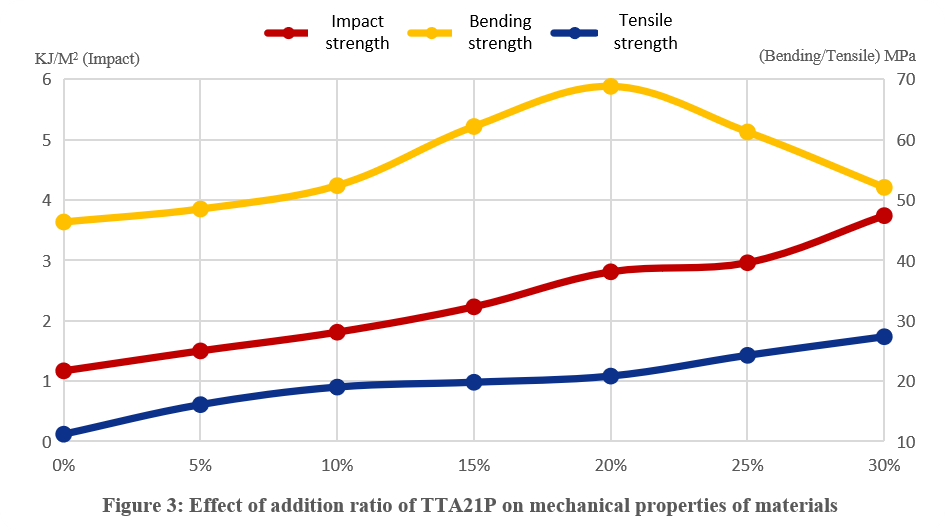

5. Effect of addition ratio of TTA21P on mechanical properties of materials

5.1 Test materials and curing conditions: TTA21P/128/ MHHPA/ BDMA and 100℃×2h+140℃×2h+180℃×1h.

5.2 Conclusion: When the addition ratio of TTA21P increases gradually within the range of 0%~30%, the impact strength and tensile strength of the material increase continuously, while the bending strength increases first and then decreases (peaking at about 20%).

In conclusion, the optimal comprehensive performance can be obtained when the addition ratio of cycloaliphatic epoxy resins TTA21P is within the range of 10%~30%. The specific ratio should be determined based on various indicators and requirements of the complete formula.